From Design to Prototyping to Production, Zhaoyida is always ready to turn your ideas into reality and provide advanced manufacturing solutions suitable for your products.

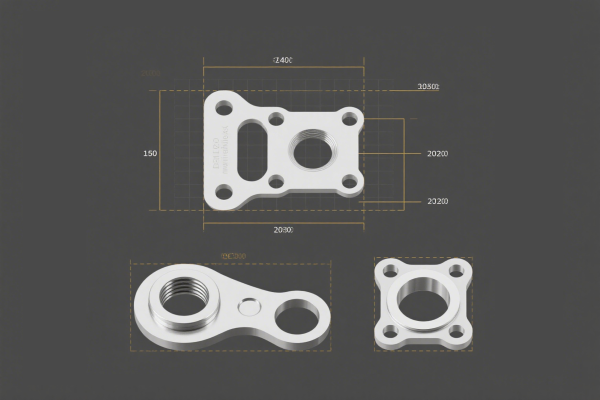

Prototyping design

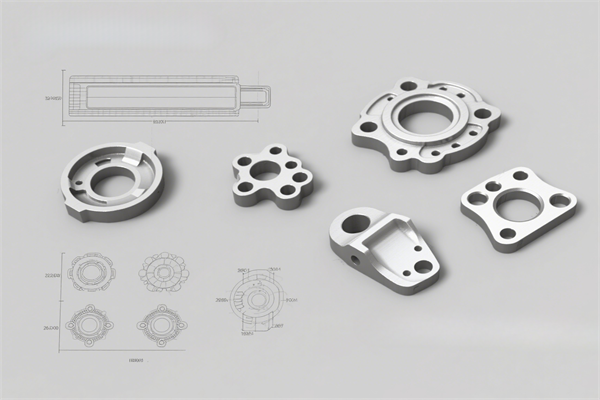

product manufacturing

Complete Prototyping & Manufacturing Capabilities

As a one-stop rapid manufacturing and prototyping company for your team, let’s watch the video to learn more about how Zhaoyida Rapid Manufacturing supports on-demand parts production and custom manufacturing.

Focused on rapid prototyping and on-demand manufacturing services

Hardware and Plastic Single Product Display

(4)_QqYBq9py.jpg)

Product Name: Electric Vehicle Parts Injection Molding Material:PC+10%GF

Electric vehicle components are injection molded with PC+10% GF, which combines the advantages of toughness, impact resistance, high rigidity, and dimensional stability to cope with complex working conditions and ensure reliable and durable components.

Custom Manufacturing Solutions For On-Demand Production

Start Your Prototyping & Manufacturing Process with Us in Just 3 Simple Steps

With just 3 simple steps, you can start your prototyping and manufacturing process with us.

Requirement analysis and design

Clarify the requirements for product functionality, performance, appearance, etc., conduct conceptual and detailed design, draw drawings or create digital models.

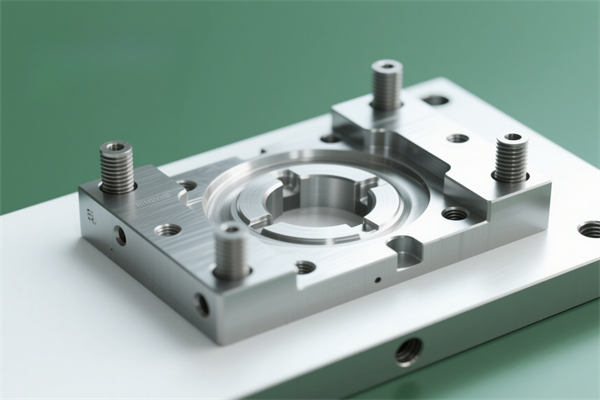

Prototype production

Based on the design plan, select appropriate materials and processes to create a prototype of the product. This may involve technologies such as 3D printing, CNC machining, and manual production.

Testing and optimization:

Conduct various tests on the prototype, such as functional testing, performance testing, reliability testing, etc., collect feedback, and optimize and improve the design

Blog

VIEW ALL →SUBSCRIBE

INQUIRY

.jpg (1)_看图王_MFr1cwRU.png)

(2)_79hMUfb1.jpg)

(3)_3fH4aPEZ.jpg)

(1)_IxP16rjT.jpg)

(5)_GX5MuIPr.jpg)

(9)_4evWudHR.jpg)

(8)_a1DdjHNR.jpg)

(7)_jPN5oaHu.jpg)

_BSXSiCcU.jpg)

(6)_a9PFXOjq.jpg)