Quality Management Systems For Machine Shop

VIEW OUR ISO 9001:2015 CERTIFICATIONZhaoyida is committed to the continuous improvement and optimization of all custom manufacturing capabilities from prototype to production, and the corresponding quality control process, including CNC machining, rapid prototyping and rapid tooling.

We strictly follow the ISO 9001 certified quality management system, based on a series of standardized production procedures and work instructions, and use advanced testing equipment to measure and inspect each production step to ensure that your project meets stringent quality specifications.

Our Quality Policy

Let Zhaoyida be the safest and most dependable choicefor your next manufacturing project.

START NEW PROJECTSInspection And Quality Control Procedures In Our CNC Machine Shop

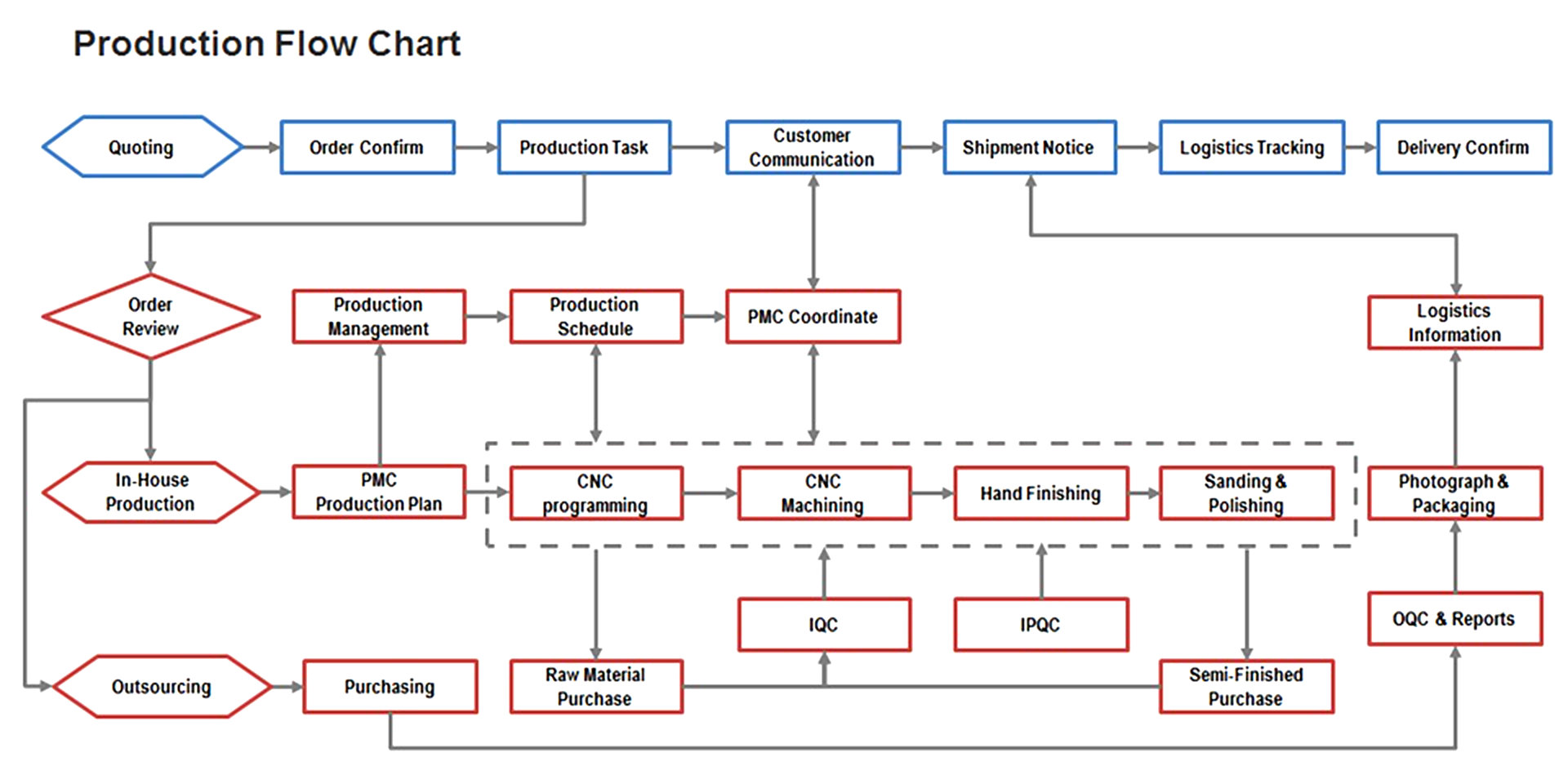

Our quality process is run through the whole projects from RFQs to production shipment.

Our quality control system covers every aspect from initial project inquiry to finished product production and delivery

Quality Inspection Equipment

SUBSCRIBE

INQUIRY

.jpg (1)_看图王_MFr1cwRU.png)