Advancing Excellence In Prototyping Clear Parts

Many prototyping applications benefit from the use of clear plastic parts to achieve optical functions, view the inside of products, or improve aesthetics. Clear prototypes and optical prototypes machining are mainly referring to the machining of transparent acrylic (PMMA) and polycarbonate (PC), and most applications choose them to get a mirror-clear effect. For example, automotive lighting lamp lens, light guides, or product external components, displays, etc.

Zhaoyida provides a range of solutions for custom clear parts and optical components to meet your functional needs, including CNC machining, vacuum casting, and injection molding. We have the expertise required to machine clear plastics without blemishes. We also have highly skilled polishing techniques to achieve optical clarity on plastic parts. Our approach to excellence allows us to fully support optical prototype development projects.

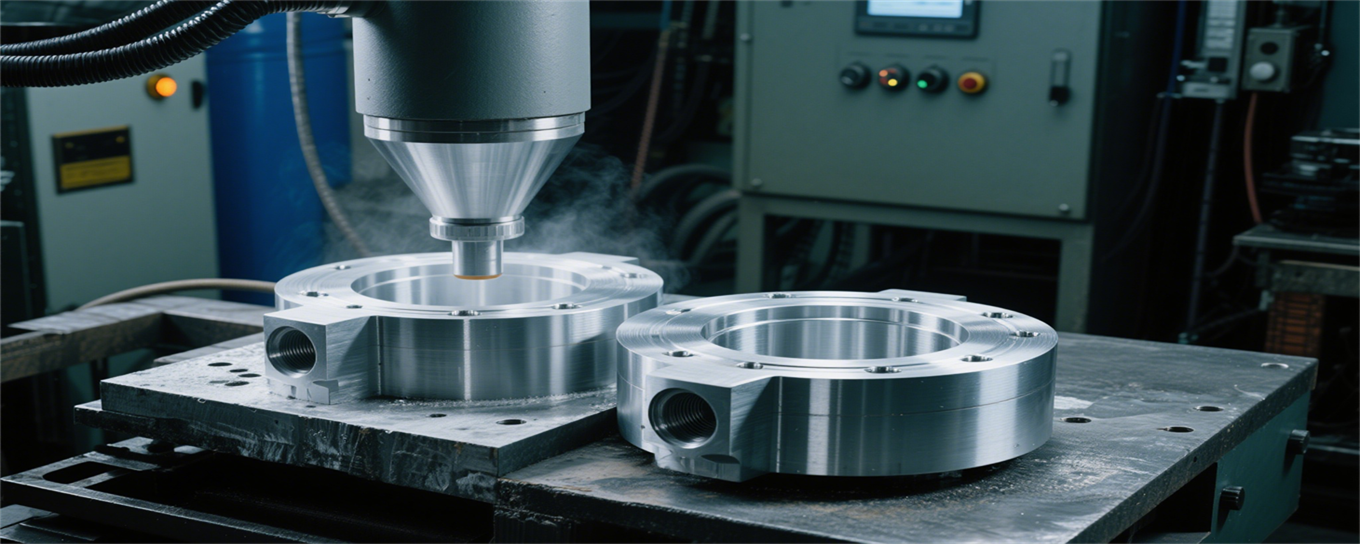

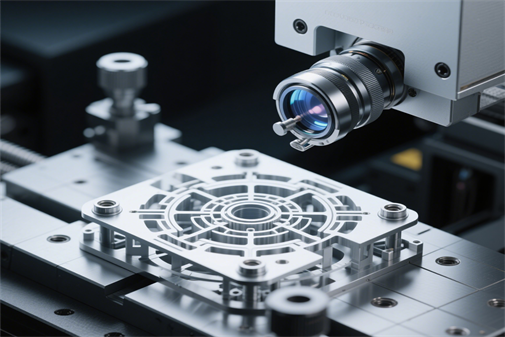

Optical Prototypes With Precision CNC Machining

high-precision

Capable of accurately controlling the complex structural dimensions of optical prototypes and meeting stringent optical performance indicators.

High quality surface

The processed surface has high flatness and low roughness, reducing optical component light loss and scattering.

Makeup mirror made of ABS material

Materials for ventilator accessories: PBT+30%GF

_KF4WFYVC.jpg)

Applications For Prototyping Clear Parts

Used for prototyping hardware models

Zhaoyida focuses on providing one-stop services for hardware mold prototypes, continuously accumulating knowledge and experience in this field. We can provide strong support at every stage, from mechanical component design review, prototype development engineering testing, to showcase vehicle projects.

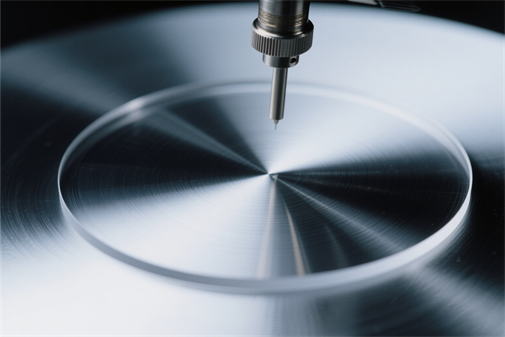

Clear Prototypes - Auto Lamp Lens

Machining experience of thin-walled clear plastic

Unparalleled hand finishing and polishing technology

Advanced two-color and multi-material (2K) molding process

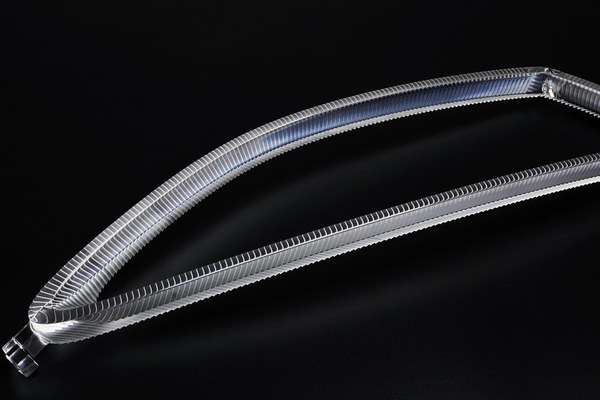

Optical Prototypes - Light Pipes & Light Guides

Machining experience of thin-walled clear plastic

Unparalleled hand finishing and polishing technology

Advanced two-color and multi-material (2K) molding process

.jpg (1)_看图王_MFr1cwRU.png)