As the pace of product design for industry increases, designers are pushing ahead with the bridge between concept and production in the fastest time possible. Industrial design prototyping is the first step in putting ideas and concepts in product design into practice, exploring solutions for product design manufacturability by moving designs into production-ready prototypes. Product design prototyping involves applications such as proof of concept, visual presentation, functional testing, engineering and production validation, and accurately communicates design intent, functional usability, material feasibility, and the working mechanism and performance of the product to manufacturers and product engineers.

Good product design should always focus on the end user first and foremost to ensure that they get the best experience with the product. Prototype design could be anything from a simple part file to models of complex assembled parts. There is nothing that brings you closer to the functionality of the final product faster than prototyping.

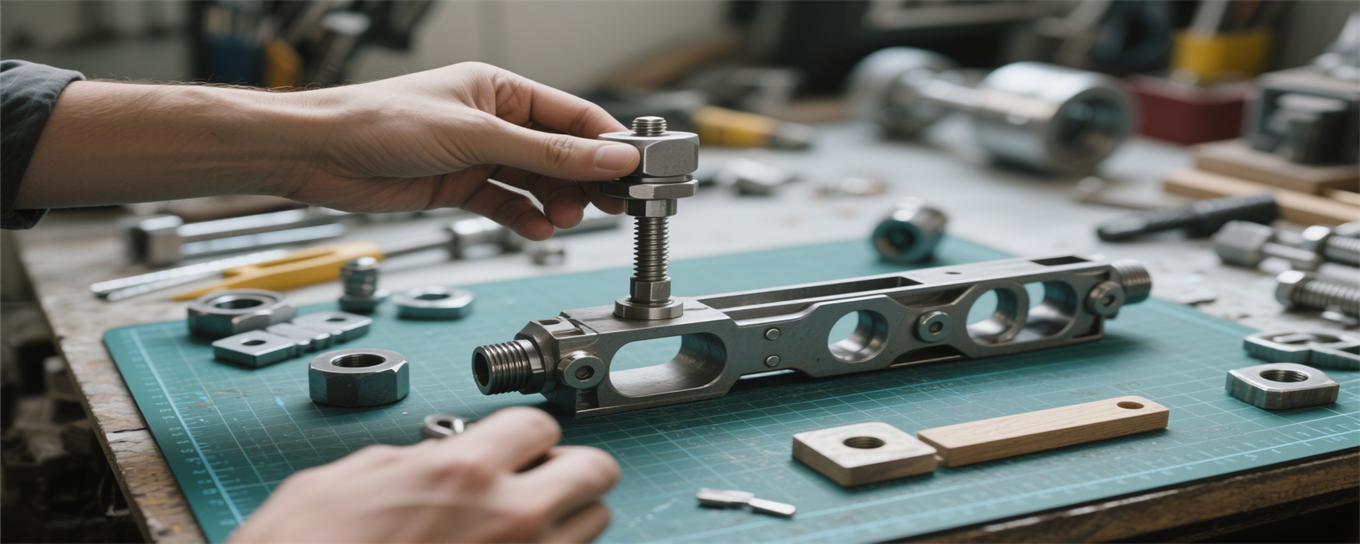

Based on this, seasoned designers always transition between concept design, CAD modeling, and prototyping to validate their ideas. This back and forth conversation between design and prototype creates an iterative process in which each tool reveals new opportunities and problems to explore and further refine.

For industrial designers, product design prototyping is always a crucial step within the creative process to help you better understand the user experience. This works both externally – presenting to clients and stakeholders – and internally – in collaborating more deeply with your team, or rallying them to support a new idea.

Industrial Prototyping and Part Manufacturing Capabilities

Zhaoyida offers comprehensive machining capabilities in prototyping and part production for your industrial design.

Comprehensive technical coverage

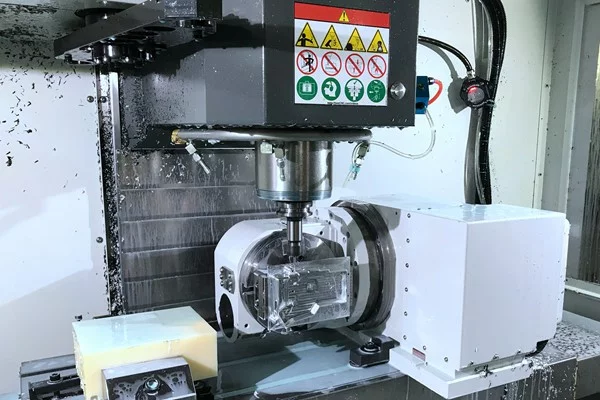

Covering multiple technologies such as 3D printing, CNC machining, injection molding, etc., adapting to different material and structural requirements.

Reliable accuracy guarantee:

With high-precision equipment and processes, strict control of prototype and part size errors ensures product quality.

Flexible and efficient production

Supports single piece prototype production to small and medium batch part production, quick response delivery, and shortens development.

Full customization of service

One-stop service from design optimization to post-processing, meeting customers' personalized functional and appearance needs

The Application And Advantages Of Prototyping In Industrial Design

Industrial design prototyping helps teams collaborate better with each other, identify and solve problems early, and improve existing designs. These applications and advantages are well worth the extra time and effort.

Industrial Design Applications

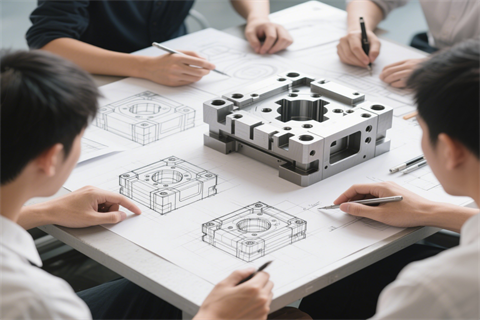

In industrial design, visualization is the core of design expression and the foundation of design discussion. From the initial 2D sketch to the refinement stage, the prototype serves as a key discussion medium, making details clearer and more realistic, effectively promoting team communication and collaboration, and driving the design from concept to implementation.

_看图王_Iwib64dg.png)

Industrial design advantages

In industrial design, visual and intuitive presentation of design concepts is the cornerstone of efficient communication. Prototype production transforms abstract concepts into entities, which are used to verify feasibility, test functionality, assist in precise evaluation and optimization, significantly improve design quality, accelerate the process of product creation and implementation, and demonstrate irreplaceable advantages in all aspects.

You Design It We Will Manufacture It For YouMake Your Ideas Into Products

START NEW PROJECTSSUBSCRIBE

INQUIRY

.jpg (1)_看图王_MFr1cwRU.png)