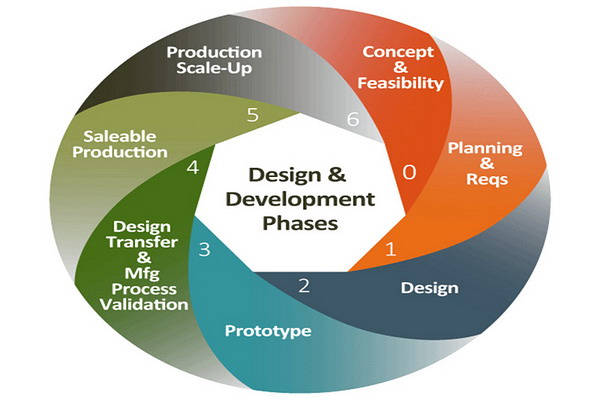

Choosing product prototype development is to quickly build a product model, validate product concepts and functions in advance, collect user feedback, optimize design solutions, and reduce development risks and costs before the product is officially developed.

There are three types of product prototypes: low fidelity prototypes, high fidelity prototypes, and functional prototypes. Low fidelity prototypes are simple and intuitive, used for quickly verifying concepts and demonstrating basic architectures; High fidelity prototypes focus on visual details and interactive effects, which can simulate product experiences more realistically; Functional prototypes focus on implementing the core functions of the product, used for testing and optimizing functional logic. The specific type to choose depends on the product development stage, goals, and requirements.

Significance Of Product Prototypes In Development Process

- Realize And Explore Concepts

In the development and implementation of product prototypes, exploring concepts refers to building preliminary models, verifying the feasibility of product creativity, exploring potential functions and user needs, and clarifying the core values and development direction of the product.

- Communicate Ideas Effectively

Collect data and feedback through high standard practice, analyze product performance and identify issues based on this, and then determine improvement ideas.

- Design Iterations More Flexible

Design iteration is more flexible, allowing for quick adjustments to the design based on various feedback, free experimentation and innovation, and improving the fit between the product and market demand.

- Move To Full Production With Confidence

After prototype development, testing and optimization, the product is mature and reliable in all aspects. With accumulated experience and technology, the team is confident that it can complete comprehensive production tasks according to standards and efficiently.

- Cost-Effective Low Volume Manufacturing

Economically efficient small batch manufacturing is the use of reasonable processes and resource allocation to control costs and ensure efficiency when producing small quantities of products, achieving a good balance between input and output.

Build Product Prototypes For Your New Product Development

Regardless of the stage of your idea, Our prototype designer has an unmatched ability to quickly create highly accurate, aesthetic, and both functional and manufacturable product prototypes. And validate your prototype design with full prototype testing.

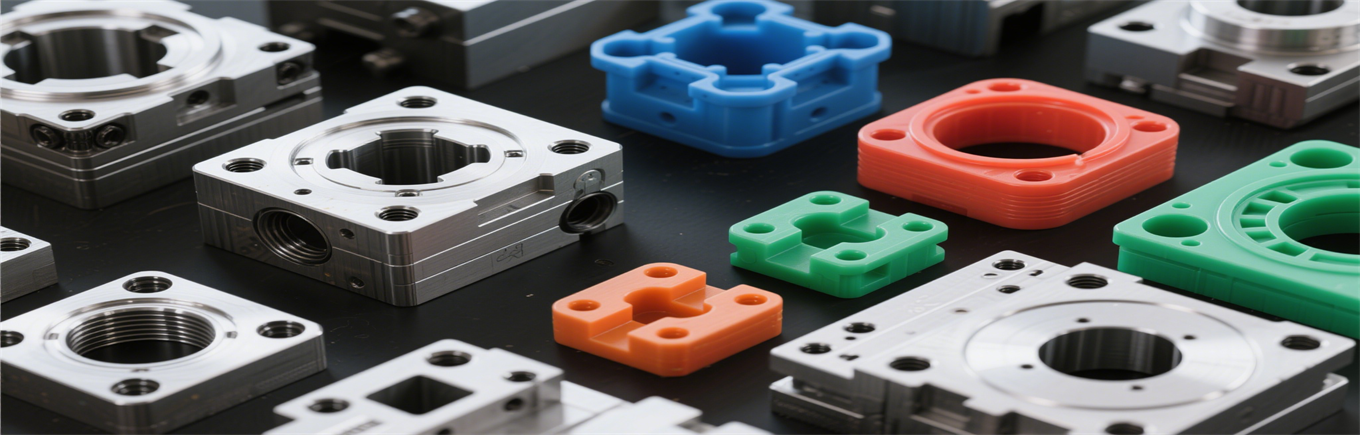

Zhaoyida's Product Prototyping Capabilities Are Available Throughout Your Development Process

Zhaoyida focuses on providing efficient product prototyping and rapid manufacturing solutions for enterprises in various industries, from commercial to consumer sectors, instrument and equipment to digital appliances. We have mastered technologies such as CNC machining, vacuum casting, rapid prototyping, and small batch injection molding, and maintain a leading position with innovative services and professional teams. Accompanying product design throughout the process, we are committed to becoming your most capable all-round product development partner.

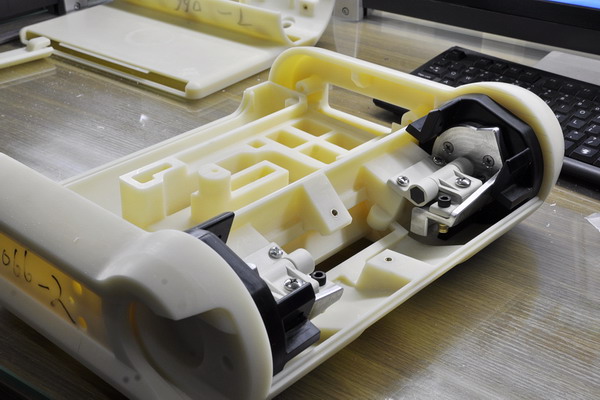

Product Prototypes of Instruments and Equipment

We have experience creating complex working mechanism product prototypes that simulate the end-use product to check the form and fit, ensuring that all components are accurately assembled with expensive industrial equipment and multi-part instruments; using the same engineering-grade plastic and metal materials as the final product, verifying the mechanical function, electrical properties, chemical resistance, thermal properties and life testing of the product. As a result, you can get a clear picture of how a part or component will operate when it represents the real environment of its actual application.

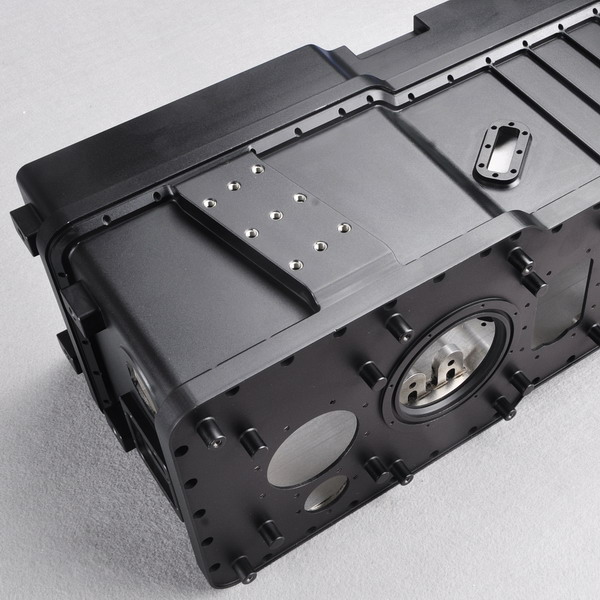

Prototyping for Commercial and Office Products

Zhaoyida's product prototype production service is customized for manufacturers of commercial and office automation equipment (OA products). The prototype is strictly built according to precise specifications, accurately reproducing core attributes such as component fitting accuracy, dimensional tolerances, and mechanical performance. With the accumulation of high-precision CNC machining technology, we can provide professional manufacturing solutions based on raw materials, processes, and precision requirements, helping to overcome engineering difficulties and predict production risks.

Prototype for Consumer and Appliances Products

In the fiercely competitive consumer goods market, Zhaoyida focuses on high-quality prototype design, ensuring timely delivery and strict cost control. We can quickly respond to project requirements, provide one-stop services from processing to surface treatment, and can produce high fidelity visual models and fully functional high fidelity prototypes. These prototypes are suitable for market research such as focus groups, user testing, exhibitions, and can also assist in design optimization iterations during the development phase.

You Generate The Concept , We Will Build ItEnd-To-End Product Development Solution

START NEW PROJECTSSUBSCRIBE

INQUIRY

.jpg (1)_看图王_MFr1cwRU.png)