Regarding optimizing product design and gaining a deeper understanding of rapid prototyping

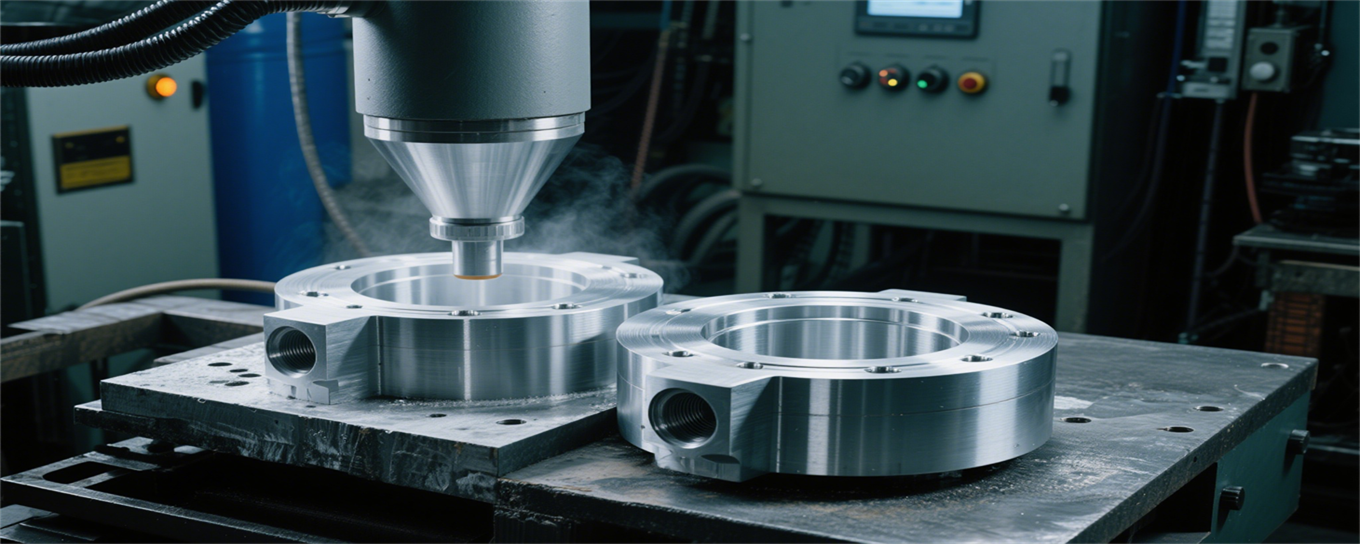

In terms of functional verification, rapid prototyping can simulate real usage scenarios and test the structural strength, assembly feasibility, and coordination of moving parts of the product. For example, by 3D printing mechanical part prototypes, their stability during actual operation can be tested, avoiding large-scale production losses caused by design issues. In addition, rapid prototyping can also be used for user testing, collecting feedback, optimizing product functionality and user experience.

From the perspective of cost and efficiency, rapid prototyping avoids the high cost and time waste caused by repeated modifications in traditional design processes. Through rapid iteration, product design can reach a better state in a short period of time, accelerating the product launch process. Whether optimizing product appearance details or enhancing internal structural rationality, in-depth understanding of rapid prototyping can provide key assistance for product design, ensuring that the final product is more competitive in the market.

SUBSCRIBE

INQUIRY

.jpg (1)_看图王_MFr1cwRU.png)

apiuser

apiuser 2025-04-23

2025-04-23 1

1